Several months ago, I saw an interesting article about a cool museum called the Neon Museum which is located in Las Vegas.

According to the museum’s website, “the Neon Museum is a non-profit 501 (c) 3 organization dedicated to collecting, preserving, studying and exhibiting iconic Las Vegas signs for educational, historic, arts and cultural enrichment.” The museum holds over 250 neon signs. Tours are given both day and, of course, at night. The main collection in the “Bone Yard” includes signage from Caesar’s Palace, The Stardust Resort and Casino, and the recently added giant guitar from the now closed Hard Rock Café.

Some of the pieces are still operational and “live” shows are given nightly. Other signs are dormant and are lit up by flood lights.

(Photos Courtesy of the Neon Museum, Las Vegas, NV)

Production of neon light tubes requires vacuum pumps and, of course, reliable vacuum measurement. Typically, glass tubes are bent into shape and then pumped to around 1 Torr and energized using a glow discharge to clean up the tube. Next, the tube is evacuated to the mTorr region. Different gases are then backfilled to a few Torr which, when excited in a glow discharge, create various colors. Neon gives the classic neon red/orange glow while carbon dioxide produces white, helium gives yellow, and mercury can be blended with neon to produce blues. In some cases, coatings on the internal surface of the glass can be used to create additional colors. When using coatings, mercury is included in the gas to ensure that UV photons are created to activate the fluorescent coating.

A nice tutorial of glow discharge characteristics with some history is given starting on page 14 in the February 2020 issue of Vacuum Technology & Coating magazine. https://digital.vtcmag.com/12727/26337/index.html

The new HVG-2020B from Teledyne Hastings is a great vacuum gauge for this application. The gauge uses two vacuum sensors: a piezoresistive sensor to measure pressures from atmosphere to 10 Torr and a thermal Pirani sensor to measure from 1 Torr to 0.1 mTorr. In between 1 and 10 Torr, the gauge uses a weighted average to ensure a smooth transition between the two sensors. The piezoresistive sensor is gas species independent, so no matter what gas is being backfilled, the piezoresistive sensor gives an accurate measurement. The Pirani sensor’s response is affected by the gas species, but the user can select a gas and the correction is made.

The new HVG-2020B from Teledyne Hastings is a great vacuum gauge for this application. The gauge uses two vacuum sensors: a piezoresistive sensor to measure pressures from atmosphere to 10 Torr and a thermal Pirani sensor to measure from 1 Torr to 0.1 mTorr. In between 1 and 10 Torr, the gauge uses a weighted average to ensure a smooth transition between the two sensors. The piezoresistive sensor is gas species independent, so no matter what gas is being backfilled, the piezoresistive sensor gives an accurate measurement. The Pirani sensor’s response is affected by the gas species, but the user can select a gas and the correction is made.

So, the next time you see a neon light, you can think about the vacuum gauge that was probably used to manufacture the gas tube. And if you’re ever in Vegas, check out the Neon Museum!

For more information about any of our vacuum gauges or our complete line of mass flow meters and controllers, we are here to help. You can contact us at hastings_instruments@teledyne.com , Live Chat on our website www.teledyne-hi.com , or call 757-723-6531 (800-950-2468). And to learn more about the HVG-2020B Vacuum Gauge, click the link below, “5 Reasons you need the HVG-2020B Vacuum Gauge.”

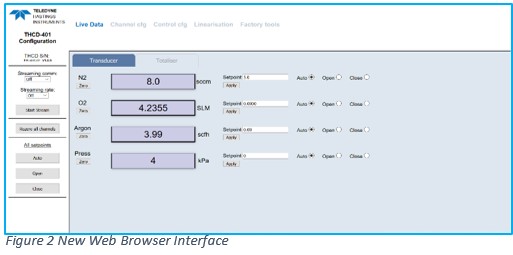

Teledyne Hastings is proud to announce our newest 4-channel power supply, controller and display, the

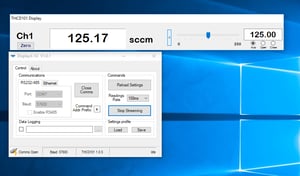

Teledyne Hastings is proud to announce our newest 4-channel power supply, controller and display, the  The addition of Ethernet communication provides access to the newest feature that the THCD-401 has to offer; the internal web server! The web server can be accessed by entering the IP address of the THCD-401 into a browser’s address bar (requires static IP address configuration on the network prior to use). While the web server feature works best in Mozilla™ Firefox®, it can be accessed via any browser you choose. Figure 2 shows the web server interface with applications along the top navigation bar and a live data stream for remote read.

The addition of Ethernet communication provides access to the newest feature that the THCD-401 has to offer; the internal web server! The web server can be accessed by entering the IP address of the THCD-401 into a browser’s address bar (requires static IP address configuration on the network prior to use). While the web server feature works best in Mozilla™ Firefox®, it can be accessed via any browser you choose. Figure 2 shows the web server interface with applications along the top navigation bar and a live data stream for remote read.

The early part of the 1950’s was prosperous for Hastings due in part to the demand for the Raydist and large military contracts as a result of the Korean War. Sales nearly tripled between 1950 and 1953 and there were almost 200 employees. Hastings had outgrown its space yet again and expanded to a 14,000 square foot building on Newcomb Avenue (current day location for Teledyne Hastings). The building was originally used as a car barn for street cars, then as a World War I armory and eventually as a manufacturing plant for ladies clothing.

The early part of the 1950’s was prosperous for Hastings due in part to the demand for the Raydist and large military contracts as a result of the Korean War. Sales nearly tripled between 1950 and 1953 and there were almost 200 employees. Hastings had outgrown its space yet again and expanded to a 14,000 square foot building on Newcomb Avenue (current day location for Teledyne Hastings). The building was originally used as a car barn for street cars, then as a World War I armory and eventually as a manufacturing plant for ladies clothing.

A small percentage of Hastings business during the early 1950’s was for instrument sales. The most important of these products were the air-meters, vacuum gauges, flow meters, accelerometers and an electronic standard cell. In order to grow this part of the business, Hastings decided to set up a manufacturer’s representative program. By the end of 1953, Hasting’s was looking forward to seeing this manufacturer’s representative program vastly increasing instrument sales.

A small percentage of Hastings business during the early 1950’s was for instrument sales. The most important of these products were the air-meters, vacuum gauges, flow meters, accelerometers and an electronic standard cell. In order to grow this part of the business, Hastings decided to set up a manufacturer’s representative program. By the end of 1953, Hasting’s was looking forward to seeing this manufacturer’s representative program vastly increasing instrument sales.

By 1947, the Hastings Instrument Company could count many successful projects. Their list of products included the following:

By 1947, the Hastings Instrument Company could count many successful projects. Their list of products included the following: After several sales pitches and demonstrations, Hastings received two large contracts for Raydist. Along with these two contracts, the company was busy building Air-Meters for commercial sales. Before selling the Air-Meters, the instruments needed to be calibrated. In those early days, calibration was done by driving down the road holding a probe out the window while someone in the passenger seat held the Air-Meter. When the car reached 5, 10, 15 etc… mph the passenger would make a note on the blank dial face and then return to the house where they would neatly letter the dial face.

After several sales pitches and demonstrations, Hastings received two large contracts for Raydist. Along with these two contracts, the company was busy building Air-Meters for commercial sales. Before selling the Air-Meters, the instruments needed to be calibrated. In those early days, calibration was done by driving down the road holding a probe out the window while someone in the passenger seat held the Air-Meter. When the car reached 5, 10, 15 etc… mph the passenger would make a note on the blank dial face and then return to the house where they would neatly letter the dial face. During this period of growth, Hastings realized that it was time to find a new location for the business. By now, there were 17 people working elbow-to-elbow at the Hastings’ home and that could not continue. The company settled on temporary location in an old brick distributorship building that had a leaky roof and flooded at spring tides, but it was at the price they could afford.

During this period of growth, Hastings realized that it was time to find a new location for the business. By now, there were 17 people working elbow-to-elbow at the Hastings’ home and that could not continue. The company settled on temporary location in an old brick distributorship building that had a leaky roof and flooded at spring tides, but it was at the price they could afford.

I

I n addition to the list of commercial instruments above, Hastings developed specialized instruments for specific customers. For example: the “Ventimeter” was used by the army to measure ventilation in clothing to keep wearers comfortable under extreme weather conditions. The Hastings Company was now growing fast and generating handsome profits for its stakeholders.

n addition to the list of commercial instruments above, Hastings developed specialized instruments for specific customers. For example: the “Ventimeter” was used by the army to measure ventilation in clothing to keep wearers comfortable under extreme weather conditions. The Hastings Company was now growing fast and generating handsome profits for its stakeholders.

Recently, I learned that certain smartphones contain an actual pressure transducer. I shared this info with a friend who insisted that the phone was not really measuring pressure, but was instead using the internet to download the pressure based on the phone’s location. Now, I had to prove them wrong.

Recently, I learned that certain smartphones contain an actual pressure transducer. I shared this info with a friend who insisted that the phone was not really measuring pressure, but was instead using the internet to download the pressure based on the phone’s location. Now, I had to prove them wrong.

So, it is true that you may be able to use your smartphone to measure vacuum in your system. However, we would like to suggest an easier way… check out our new

So, it is true that you may be able to use your smartphone to measure vacuum in your system. However, we would like to suggest an easier way… check out our new  In September 1944, the Hastings Instrument Company started to take shape. For quite some time, Charles & Mary conducted the business out of their home. They received their first order in December from the Naval Aircraft Factory in Philadelphia for $800. The order was for a rotary magnetic switch for commutating electrical circuits.

In September 1944, the Hastings Instrument Company started to take shape. For quite some time, Charles & Mary conducted the business out of their home. They received their first order in December from the Naval Aircraft Factory in Philadelphia for $800. The order was for a rotary magnetic switch for commutating electrical circuits.  Business continued to grow. Seventeen employees would arrive at the Hastings home around 7pm on Monday, Wednesday and Friday to work on their electronic projects (see image on right). During the day, Mary would take care of miscellaneous projects. On one occasion, Mary agreed to have some Raydist cabinets painted by the time Charles came home. Unfortunately, the air compressor was out of air so Mary came up with another plan. She would take the car to the nearby service station and put as much air in the tires as she could without them bursting. She would then drive back home, attach her paint sprayer to the tires, and paint the Raydist cabinets

Business continued to grow. Seventeen employees would arrive at the Hastings home around 7pm on Monday, Wednesday and Friday to work on their electronic projects (see image on right). During the day, Mary would take care of miscellaneous projects. On one occasion, Mary agreed to have some Raydist cabinets painted by the time Charles came home. Unfortunately, the air compressor was out of air so Mary came up with another plan. She would take the car to the nearby service station and put as much air in the tires as she could without them bursting. She would then drive back home, attach her paint sprayer to the tires, and paint the Raydist cabinets  until her tires were almost flat. She did this several times to complete the project before Charles came home. The business activities took a toll on the Hastings home. The roof leaked and needed to be replaced from all the antennas mounted to it (see image on left), the driveway needed to be replaced from the damage of delivery trucks, Mary’s oven smelled like paint which caused some challenges when meal time came.

until her tires were almost flat. She did this several times to complete the project before Charles came home. The business activities took a toll on the Hastings home. The roof leaked and needed to be replaced from all the antennas mounted to it (see image on left), the driveway needed to be replaced from the damage of delivery trucks, Mary’s oven smelled like paint which caused some challenges when meal time came. In January 1946, Hastings received their first order for a Raydist. The Air Material Command at Wright Field in Cleveland Ohio wanted a single-dimensional Raydist system to use during aerial photography and mapping. The final product was hand-delivered by Charles himself in October. (see image on right and below)

In January 1946, Hastings received their first order for a Raydist. The Air Material Command at Wright Field in Cleveland Ohio wanted a single-dimensional Raydist system to use during aerial photography and mapping. The final product was hand-delivered by Charles himself in October. (see image on right and below)

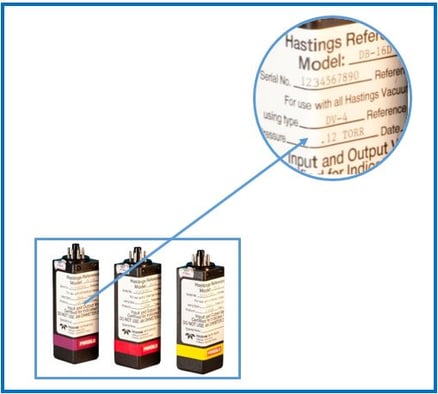

This year, 2019, marks the 75th anniversary of Hastings Instruments and we will be celebrating all year long by discussing some of our past while focusing on our future. This month, I’d like to tell you a little about our glass shop.

This year, 2019, marks the 75th anniversary of Hastings Instruments and we will be celebrating all year long by discussing some of our past while focusing on our future. This month, I’d like to tell you a little about our glass shop.

We are proud of our long history of quality craftwork, not only in the glass shop, but throughout all of our vacuum and thermal mass flow product lines here at Teledyne Hastings. The same tradition of quality goes into our newest products including the

We are proud of our long history of quality craftwork, not only in the glass shop, but throughout all of our vacuum and thermal mass flow product lines here at Teledyne Hastings. The same tradition of quality goes into our newest products including the  Ever wonder where the idea or dream of Hastings originated? Well as part 1 of our anniversary year blog posts, we thought this would be a good place to start. Charles Hastings at the age of 10 was bitten by the radio bug and began to build and experiment with radio gear. In 1930, at the age of 16, Charles Hastings found an opportunity to fund his experiments by fixing other people’s radios. Many families had radios at this point, but they were very unreliable and frequently needed minor repairs. Charles would fix radios to earn money to buy parts for his own experiments.

Ever wonder where the idea or dream of Hastings originated? Well as part 1 of our anniversary year blog posts, we thought this would be a good place to start. Charles Hastings at the age of 10 was bitten by the radio bug and began to build and experiment with radio gear. In 1930, at the age of 16, Charles Hastings found an opportunity to fund his experiments by fixing other people’s radios. Many families had radios at this point, but they were very unreliable and frequently needed minor repairs. Charles would fix radios to earn money to buy parts for his own experiments. Teledyne Hastings is proud to announce the release of the THCD-101 single channel power supply, controller and display. The THCD-101 can be used to operate a wide variety of mass flow meters and controllers as well as vacuum gauges and pressure transducers. The THCD-101 uses bright OLED digits which makes the display easy to view, even from a distance. The THCD-101 is extremely versatile in its configurable range and can be set up to display any unit of measurement through customizable alphanumeric characters. The power supply provides stable ±15 VDC and +24 VDC levels which can be used to operate a variety of measurement and control instruments. The display and readout features a high accuracy of ±(0.02% of Reading + 0.01% of Full Scale). The user can also set relay alarms for the control of other processes. The THCD-101 is configured at the factory to match the user’s requirements for range & units so it is ready to use right out-of-the-box.

Teledyne Hastings is proud to announce the release of the THCD-101 single channel power supply, controller and display. The THCD-101 can be used to operate a wide variety of mass flow meters and controllers as well as vacuum gauges and pressure transducers. The THCD-101 uses bright OLED digits which makes the display easy to view, even from a distance. The THCD-101 is extremely versatile in its configurable range and can be set up to display any unit of measurement through customizable alphanumeric characters. The power supply provides stable ±15 VDC and +24 VDC levels which can be used to operate a variety of measurement and control instruments. The display and readout features a high accuracy of ±(0.02% of Reading + 0.01% of Full Scale). The user can also set relay alarms for the control of other processes. The THCD-101 is configured at the factory to match the user’s requirements for range & units so it is ready to use right out-of-the-box. The THCD-101 now includes digital communication via a USB ‘C’ connection or Ethernet (TCP/IP). When the power supply is connected via Ethernet, the THCD-101 provides a web server for operation and instrument configuration. The web server can be accessed by entering the IP address of the device into a browser address bar (requires static IP address configuration on the network prior to use). This allows the user control of various settings within the device and to read the devices current reading. Note that the IP Address can be changed through the menus of THCD-101. In addition to the THCD-101 web server, standalone DisplayX software can be downloaded free of charge from the Teledyne Hastings website. Should the user need to change the THCD-101’s setup, the DisplayX software or Ethernet web server is extremely helpful in streamlining this process.

The THCD-101 now includes digital communication via a USB ‘C’ connection or Ethernet (TCP/IP). When the power supply is connected via Ethernet, the THCD-101 provides a web server for operation and instrument configuration. The web server can be accessed by entering the IP address of the device into a browser address bar (requires static IP address configuration on the network prior to use). This allows the user control of various settings within the device and to read the devices current reading. Note that the IP Address can be changed through the menus of THCD-101. In addition to the THCD-101 web server, standalone DisplayX software can be downloaded free of charge from the Teledyne Hastings website. Should the user need to change the THCD-101’s setup, the DisplayX software or Ethernet web server is extremely helpful in streamlining this process. As outlined above, the THCD-101 contains all the great features of the legacy THCD-100 while adding new and improved features such as USB & Ethernet digital communications and a bright OLED display. Even with these powerful additions, the instrument keeps the same 1/8 DIN size while offering a shorter depth than the previous display & readout!

As outlined above, the THCD-101 contains all the great features of the legacy THCD-100 while adding new and improved features such as USB & Ethernet digital communications and a bright OLED display. Even with these powerful additions, the instrument keeps the same 1/8 DIN size while offering a shorter depth than the previous display & readout!

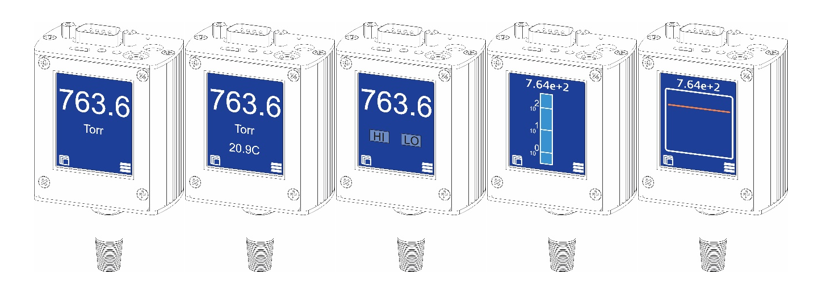

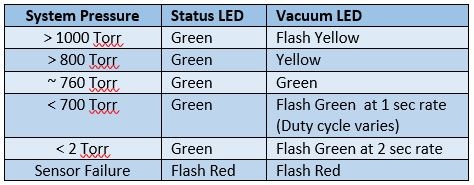

We at Teledyne Hastings Instruments are pleased to introduce the newest member of our vacuum measurement portfolio, the HVG-2020A. The HVG-2020A is a piezoresistive vacuum sensor with an optional touchscreen display that reads from 0.1-1000 Torr. The sensor uses 316 Stainless Steel as the wetted material and provides a gas independent pressure measurement, meaning your measurement will be accurate no matter what gas species is being used. The HVG-2020A features an excellent accuracy rating of ±(0.1% of Reading + 0.5 Torr). This rugged sensor comes in a number of system connections for ease of installation: 1/8” NPT, 1/4” VCR®, 1.33” Mini-CF, 2.75” CF, KF-16, KF-25, 1/2” Weld Stub, and 1/2” VCR. Let’s talk about some of the powerful features that allows the HVG-2020A to stand out.

We at Teledyne Hastings Instruments are pleased to introduce the newest member of our vacuum measurement portfolio, the HVG-2020A. The HVG-2020A is a piezoresistive vacuum sensor with an optional touchscreen display that reads from 0.1-1000 Torr. The sensor uses 316 Stainless Steel as the wetted material and provides a gas independent pressure measurement, meaning your measurement will be accurate no matter what gas species is being used. The HVG-2020A features an excellent accuracy rating of ±(0.1% of Reading + 0.5 Torr). This rugged sensor comes in a number of system connections for ease of installation: 1/8” NPT, 1/4” VCR®, 1.33” Mini-CF, 2.75” CF, KF-16, KF-25, 1/2” Weld Stub, and 1/2” VCR. Let’s talk about some of the powerful features that allows the HVG-2020A to stand out.

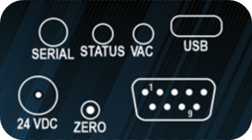

Analog I/O: The HVG-2020A has a 9 pin D-sub connector on top of the assembly that allows an analog output signal to be measured amongst other features. The selected linear analog output signal is proportional to the full scale range of the sensor (1000 Torr). Available outputs are 0-1 VDC, 0-5 VDC, 0-10 VDC, 0-20 mA, and 4-20 mA. The sensor will come configured from the factory with one of these outputs active, but can be easily changed by the user should output requirements change. Through the touchscreen display, there is a menu that allows the user to cycle through the available output options. If the HVG-2020A was configured without a touchscreen, the analog output can be changed via digital communications, which we’ll talk about in the next section. In addition to the analog output, the 9 pin D-sub will have Hi & Lo set points. The Hi set point is active when the pressure is above the set value and the Lo set point is active when the pressure is below the set value. Finally, the 9 pin D-sub has a pin for input power. The HVG-2020A can accept 12-36 VDC for power. In the event, the user doesn’t have 12-36 VDC to send via the 9 pin D-sub, there’s a 24 VDC input connection port that’s compatible with a bayonet-style power supply.

Analog I/O: The HVG-2020A has a 9 pin D-sub connector on top of the assembly that allows an analog output signal to be measured amongst other features. The selected linear analog output signal is proportional to the full scale range of the sensor (1000 Torr). Available outputs are 0-1 VDC, 0-5 VDC, 0-10 VDC, 0-20 mA, and 4-20 mA. The sensor will come configured from the factory with one of these outputs active, but can be easily changed by the user should output requirements change. Through the touchscreen display, there is a menu that allows the user to cycle through the available output options. If the HVG-2020A was configured without a touchscreen, the analog output can be changed via digital communications, which we’ll talk about in the next section. In addition to the analog output, the 9 pin D-sub will have Hi & Lo set points. The Hi set point is active when the pressure is above the set value and the Lo set point is active when the pressure is below the set value. Finally, the 9 pin D-sub has a pin for input power. The HVG-2020A can accept 12-36 VDC for power. In the event, the user doesn’t have 12-36 VDC to send via the 9 pin D-sub, there’s a 24 VDC input connection port that’s compatible with a bayonet-style power supply. Digital I/O: As mentioned earlier, the HVG-2020A has a few different methods digital communication can be established. First and easiest is the micro-USB port on top of the gauge. This will allow the instrument to be directly connected to a computer without the need for adapters or extra wiring. There is also a 4-conductor TRRS jack on top of the instrument. This port can be used for daisy-chaining gauges together with RS485 or a standard RS232 communication connection. Finally, the 9 pin D-sub will have two pins designated for TTL serial communication. These digital communications (with the exception of TTL) can be connected to a PC and used with our Free Windows software for the HVG-2020A. The software has a number of features including data logging and customization/configuration of the gauge. Digital communication also allows for command syntax to be sent manually to the instrument. These commands are especially important if the HVG-2020A was ordered without a touchscreen display. Through digital communication, the user can issue commands that change the analog output, adjust set point values, stream pressure readings, or change pressure units, just to name a few.

Digital I/O: As mentioned earlier, the HVG-2020A has a few different methods digital communication can be established. First and easiest is the micro-USB port on top of the gauge. This will allow the instrument to be directly connected to a computer without the need for adapters or extra wiring. There is also a 4-conductor TRRS jack on top of the instrument. This port can be used for daisy-chaining gauges together with RS485 or a standard RS232 communication connection. Finally, the 9 pin D-sub will have two pins designated for TTL serial communication. These digital communications (with the exception of TTL) can be connected to a PC and used with our Free Windows software for the HVG-2020A. The software has a number of features including data logging and customization/configuration of the gauge. Digital communication also allows for command syntax to be sent manually to the instrument. These commands are especially important if the HVG-2020A was ordered without a touchscreen display. Through digital communication, the user can issue commands that change the analog output, adjust set point values, stream pressure readings, or change pressure units, just to name a few.