Teledyne Hastings is working to expand our throughput so that we can better serve our customers by meeting increased demand while decreasing lead times. Over the last several months, we have added and improved calibration systems in both our vacuum and flow production areas. We have also purchased a new vacuum furnace which increases our production capacity. In this blog, we will describe what a vacuum furnace is, how it functions, and how we use it.

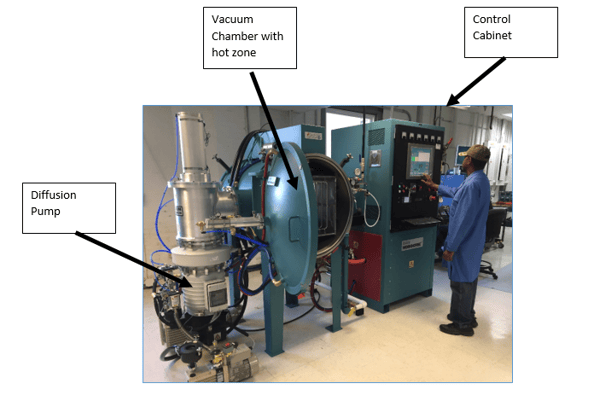

A picture of our newest vacuum furnace is shown below. The three major components of the vacuum furnace, from left to right, are the high-speed diffusion pump, the vacuum chamber with a high temperature hot zone, and the control cabinet. The diffusion pump is capable of pumping 180,000 lpm. While the pumping speed may seem unnecessarily high for the given volume, keep in mind that the gas load, at high temperature, can be very high. The diffusion pump is connected to the hot zone chamber via a large right angle vacuum valve. The diffusion pump is backed by a rotary vane vacuum pump. Pressures in the foreline can be monitored by using a Teledyne DV-6R vacuum gauge tube. The base pressure of the system, with the heat zone at room temperature approaches 1 x 10-6 Torr.

Leon Whitehead at the controls of the new vacuum furnace.

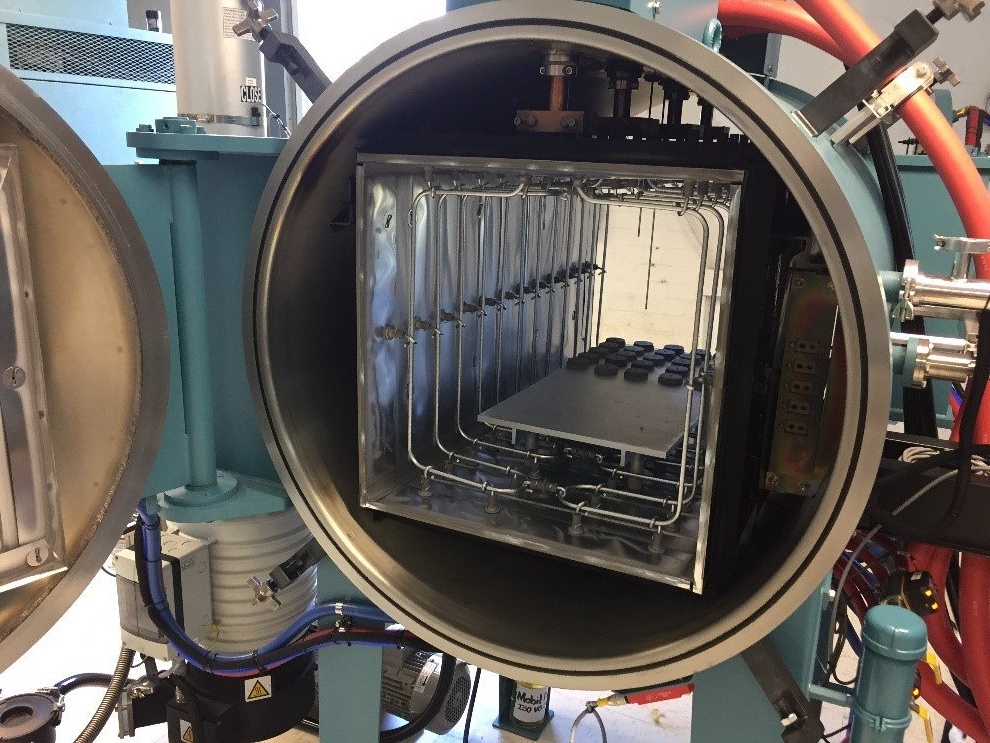

The hot zone is the heart of the vacuum furnace. A picture showing the inside of the hot zone is shown below. The effective hot zone size is 12”w x 12” h x 24” d. The molybdenum rod elements inside the hot zone are resistively heated once the system has reached sufficient vacuum. Under vacuum, the hot zone can reach temperatures exceeding 1300°C (2372°F).

Inside the hot zone. Note the series of Molybdenum rod elements.

Inside the hot zone. Note the series of Molybdenum rod elements.

The vacuum furnace is controlled by a touchscreen panel with PLC. The operator can select and execute a pre-programmed temperature/time profile for a given task. In addition, pressure and temperature at various locations on the system are monitored and displayed. The control cabinet also includes the transformers, contactors, and fuses.

Teledyne uses our vacuum furnaces for both fusing and brazing operations - all while precisely controlling the environmental conditions within the hot zone. In a typical schedule, the system is pumped out to its base pressure and then the hot zone is brought up to 800°C. After reaching this temperature, the hot zone is held for a period of 20 minutes. Next, the hot zone is slowly ramped to 1100°C, which takes about an hour. The hot zone is then held there for up to 1 ½ hours.

Teledyne Hastings Instruments is an ISO 9001:2008 certified manufacturer and we produce a complete line of instruments for precise measurement and control of vacuum, pressure, and gas flow. Our vacuum furnaces and the corresponding Quality Work Instructions deliver consistent results, which in turn provide our customers with high quality instrumentation. For information on Teledyne Hastings and our Mass Flow Meters and Controllers or Vacuum Gauges, please visit www.teledyne-hi.com or click the button below.