Thermal mass flow measurement instruments are typically separated into two main categories: Mass Flow Meters and Mass Flow Controllers. It’s estimated that over 90% of mass flow measurement instruments sold are mass flow controllers. So, it’s no surprise that most mass flow application conversations focus on mass flow controllers. Notwithstanding, there are still numerous applications for which mass flow meters are critical.

The following are common applications for mass flow meters (also known as thermal mass flow meters):

| Leak Detection | Gas Custody Transfer | Air Quality Monitoring |

| Porosity Measurement | Filter Testing | Fuel Cell Testing |

| Vacuum Pump Performance | Compressor Performance | Valve Performance |

| Calibration Transfer Standard | Combustion Gas Monitoring | Gas Sampling |

| Radiation Monitoring | Welding Shield Gas Monitoring | Thermal Spraying |

One popular application for mass flow meters is leak testing. It’s often used on products where failure is not an option. For that reason, it is widely accepted in the aerospace, automotive, and medical industries. High throughput leak detection using mass flow meters is a nondestructive testing method that offers a fast, clean, precise, and affordable solution for parts manufacturers seeking to perform leak testing on 100% of their products.

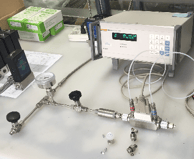

A typical test stand is shown in Figure 1. For high throughput leak detection, a pressurized manifold has multiple connections for mass flow meters. On the outlet side of each flow meter is an isolation valve and the test part. When the isolation valve is opened, test part leaks will be noted by the movement of clean dry air across the flow meter. The test part is only exposed to clean dry air.

How does leak detection with mass flow meters compare to alternative methods? It’s faster than pressure decay testing and helium leak detectors. It’s also cleaner than hydrotesting, bubble testing, and liquid penetrate testing.

To learn more, visit our Application Note:

Common products for which high throughput leak detection has been implemented include:

- Automotive Parts such as fuel injectors, brake components, exhaust systems, emission components, fuel pumps, fuel tanks, power steering systems, air conditioning systems, engine blocks, cylinder heads, transmission castings

- Aerospace Parts such as jet engine components, heat exchangers, cabin valves, oxygen delivery systems, hydraulic systems, air conditioning systems, brake systems

- Other: medical devices, filters, space suits, and much more

Frequently Asked Questions (FAQS)

Q: What’s the difference between a thermal mass flow meter and mass flow controller?

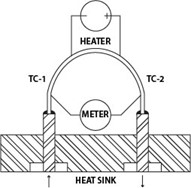

A: A thermal mass flow meter measures flow using a thermal flow sensor but does not include a proportional control valve and does not control gas flow. While a thermal mass flow controller will both measure and control gas flow, according to a command signal (setpoint). For accurate flow control, the controller measures and adjusts the gas flow using a precise, proportional control valve to maintain stable control of the flow rate based on the readings from the heated sensor.

Q: Are thermal flow meters gas specific?

A: A thermal mass flow meter is built for a user’s specific operating conditions. Teledyne Hastings' thermal flow meters are thermal based, so measurements are gas specific. For example, there would be a difference in heat conductivity between natural gas vs compressed air. Our thermal mass flow meters are built to cover a user's flow range and gas type.

Q: What does SCCM stand for?

A: SCCM stands for Standard Cubic Centimeters per Minute. This is a unit of measure for gas molecular flow rate (often referred to as mass flow). In standardized volumetric flow units, the reference conditions, or “STP" temperature and pressure, define the amount of gas by determining the number of gas molecules using the Ideal Gas Law.

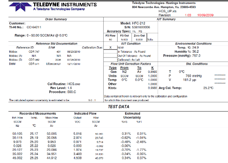

Calibration is the cornerstone of measurement accuracy, ensuring that instruments deliver reliable and precise data. Thermal mass flow meters play a pivotal role in providing a dependable solution for various industries. The calibration of these instruments is a critical factor that demands meticulous attention. In this blog, we delve into the intricacies of thermal mass flow calibration, unraveling the science behind it and its significance in achieving accurate measurements.

Calibration is the cornerstone of measurement accuracy, ensuring that instruments deliver reliable and precise data. Thermal mass flow meters play a pivotal role in providing a dependable solution for various industries. The calibration of these instruments is a critical factor that demands meticulous attention. In this blog, we delve into the intricacies of thermal mass flow calibration, unraveling the science behind it and its significance in achieving accurate measurements.