Teledyne Hastings Instruments introduced the IP-67 Enclosure Version for our high accuracy Digital 300 Series of thermal mass flow meters and flow controllers in 2018. The IP, or Ingress Protection rating, describes the instrument’s ability to operate in challenging environments. The first number, 6, indicates that the flow instrument has total protection against dust (particulate). That’s the highest-level of dust protection achievable under the IP Code. The second number, 7, refers to protection from liquids.

The Digital 300 Series with optional IP-67 enclosure can withstand water immersion up to one (1) meter for thirty (30) minutes. While it may not be obvious to everyone, it offers the liquid protection of the one meter / thirty-minute immersion as well as all lesser liquid codes (from dripping water through powerful water jets).

For more specific details on IP-67 and Ingress Protection ratings, please see our previous blog: Digital Flow Meters and Controllers now protected against dust and water - what that means for you!

What are the benefits of a mass flow meter (MFM) or mass flow controller (MFC) with IP-67 rating? It’s two-fold:

- Employee safety is every employer’s primary concern. IP-67 enclosures help to protect your employees from making accidental contact with hazardous electrical components and potential electrical shock.

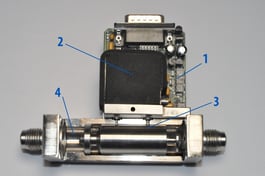

- IP-67 enclosures also help protect your equipment from the ingress of solid particles and/or liquids. Most MFC enclosures contain a PCB assembly, thermal flow sensor, and a proportional control valve. By protecting your MFC from particulate contamination and/or moisture, you prolong the service-life of those components.

This protection against dust and liquids makes IP-67 MFCs ideal for demanding indoor and outdoor applications. Whether it’s a heavy-dust industrial environment or in a facility with routine sanitary washdown requirements, the Teledyne Hastings Instruments Digital 300 Series IP-67 MFCs endure.

Common applications include:

- Food and Beverage

- Heat Treating/Metals Processing

- Environmental Monitoring

- Biotech/Pharmaceutical

- Chemical/Petrochemical

- Gas Distribution

All internal components of the Digital 300 Series IP-67 MFMs and MFCs are either gasket or o-ring sealed for ingress protection. The electronics interface uses a 12-pin circular connector that facilitates Power (24vdc, Common, and Ground), Analog Input / Output (0-5vdc, 0-10vdc, 4-20mA, or 0-20mA), and Digital Communication (RS232 or RS485).

All Digital 300 Series models (sizes) are available with the IP-67 option. These sizes combine to offer complete coverage from a minimum Full Scale flow rate of 5 sccm up to a maximum Full Scale flow rate of 10,000 SLM of N2 or equivalent. Selection details for each model are illustrated in this table:

| Size | MFM Model | MFC Model | Nominal Tubing | Maximum Flow (N2 Equiv.) | IP-67 Option |

| S | HFM-D-300A | HFC-D-302A | 1/8" and 1/4" | 25 SLM | |

| M | HFM-D-301A | HFC-D-303A | 1/2" and 3/4" | 1,000 SLM | |

| L | HFM-D-305A | HFC-D-307A | 1" | 3,000 SLM | |

| XL | HFC-D-306A | HFC-D-308A | 2" | 10,000 SLM |

Most features of the Digital 300 Series MFMs and MFCs are supported by the IP-67 version. These include the totalizer, valve over-ride, soft start, fold-over protection and many more.

Visit https://www.teledyne-hi.com/en-us/what-we-do/thermal-mass-flow to learn more about Teledyne Hastings Instruments mass flow meters and mass flow controllers.

If you have questions about mass flow controllers, feel free to contact us by phone (+1-757-723-6531 or 1-800-950-2468), email Hastings_Instruments@Teledyne.com, or via Live Chat on our website www.teledyne-hi.com.

Most people are aware that the HVG-2020B wide range vacuum gauge has an optional display, but not everyone realizes that it's much more than just a display. It's actually a color touchscreen display and is packed with features. Let's take a look.

Most people are aware that the HVG-2020B wide range vacuum gauge has an optional display, but not everyone realizes that it's much more than just a display. It's actually a color touchscreen display and is packed with features. Let's take a look.

The HVG-2020B offers multiple linear and logarithmic analog output signal options.

The HVG-2020B offers multiple linear and logarithmic analog output signal options.

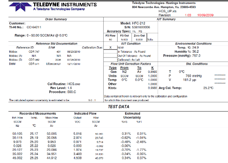

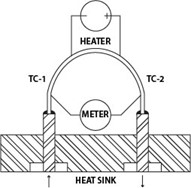

Calibration is the cornerstone of measurement accuracy, ensuring that instruments deliver reliable and precise data. Thermal mass flow meters play a pivotal role in providing a dependable solution for various industries. The calibration of these instruments is a critical factor that demands meticulous attention. In this blog, we delve into the intricacies of thermal mass flow calibration, unraveling the science behind it and its significance in achieving accurate measurements.

Calibration is the cornerstone of measurement accuracy, ensuring that instruments deliver reliable and precise data. Thermal mass flow meters play a pivotal role in providing a dependable solution for various industries. The calibration of these instruments is a critical factor that demands meticulous attention. In this blog, we delve into the intricacies of thermal mass flow calibration, unraveling the science behind it and its significance in achieving accurate measurements.

We are starting a new blog series where we will introduce you to some of the key employees here at Teledyne Hastings. Our first blog in this series will focus on our domestic sales manager, Will Harrison.

We are starting a new blog series where we will introduce you to some of the key employees here at Teledyne Hastings. Our first blog in this series will focus on our domestic sales manager, Will Harrison.  Will Harrison (right) after finishing the 2022 Honolulu Marathon. Brother Glen is on the left.

Will Harrison (right) after finishing the 2022 Honolulu Marathon. Brother Glen is on the left.

The early part of the 1950’s was prosperous for Hastings due in part to the demand for the Raydist and large military contracts as a result of the Korean War. Sales nearly tripled between 1950 and 1953 and there were almost 200 employees. Hastings had outgrown its space yet again and expanded to a 14,000 square foot building on Newcomb Avenue (current day location for Teledyne Hastings). The building was originally used as a car barn for street cars, then as a World War I armory and eventually as a manufacturing plant for ladies clothing.

The early part of the 1950’s was prosperous for Hastings due in part to the demand for the Raydist and large military contracts as a result of the Korean War. Sales nearly tripled between 1950 and 1953 and there were almost 200 employees. Hastings had outgrown its space yet again and expanded to a 14,000 square foot building on Newcomb Avenue (current day location for Teledyne Hastings). The building was originally used as a car barn for street cars, then as a World War I armory and eventually as a manufacturing plant for ladies clothing.

A small percentage of Hastings business during the early 1950’s was for instrument sales. The most important of these products were the air-meters, vacuum gauges, flow meters, accelerometers and an electronic standard cell. In order to grow this part of the business, Hastings decided to set up a manufacturer’s representative program. By the end of 1953, Hasting’s was looking forward to seeing this manufacturer’s representative program vastly increasing instrument sales.

A small percentage of Hastings business during the early 1950’s was for instrument sales. The most important of these products were the air-meters, vacuum gauges, flow meters, accelerometers and an electronic standard cell. In order to grow this part of the business, Hastings decided to set up a manufacturer’s representative program. By the end of 1953, Hasting’s was looking forward to seeing this manufacturer’s representative program vastly increasing instrument sales. By 1947, the Hastings Instrument Company could count many successful projects. Their list of products included the following:

By 1947, the Hastings Instrument Company could count many successful projects. Their list of products included the following: After several sales pitches and demonstrations, Hastings received two large contracts for Raydist. Along with these two contracts, the company was busy building Air-Meters for commercial sales. Before selling the Air-Meters, the instruments needed to be calibrated. In those early days, calibration was done by driving down the road holding a probe out the window while someone in the passenger seat held the Air-Meter. When the car reached 5, 10, 15 etc… mph the passenger would make a note on the blank dial face and then return to the house where they would neatly letter the dial face.

After several sales pitches and demonstrations, Hastings received two large contracts for Raydist. Along with these two contracts, the company was busy building Air-Meters for commercial sales. Before selling the Air-Meters, the instruments needed to be calibrated. In those early days, calibration was done by driving down the road holding a probe out the window while someone in the passenger seat held the Air-Meter. When the car reached 5, 10, 15 etc… mph the passenger would make a note on the blank dial face and then return to the house where they would neatly letter the dial face. During this period of growth, Hastings realized that it was time to find a new location for the business. By now, there were 17 people working elbow-to-elbow at the Hastings’ home and that could not continue. The company settled on temporary location in an old brick distributorship building that had a leaky roof and flooded at spring tides, but it was at the price they could afford.

During this period of growth, Hastings realized that it was time to find a new location for the business. By now, there were 17 people working elbow-to-elbow at the Hastings’ home and that could not continue. The company settled on temporary location in an old brick distributorship building that had a leaky roof and flooded at spring tides, but it was at the price they could afford.

I

I n addition to the list of commercial instruments above, Hastings developed specialized instruments for specific customers. For example: the “Ventimeter” was used by the army to measure ventilation in clothing to keep wearers comfortable under extreme weather conditions. The Hastings Company was now growing fast and generating handsome profits for its stakeholders.

n addition to the list of commercial instruments above, Hastings developed specialized instruments for specific customers. For example: the “Ventimeter” was used by the army to measure ventilation in clothing to keep wearers comfortable under extreme weather conditions. The Hastings Company was now growing fast and generating handsome profits for its stakeholders.