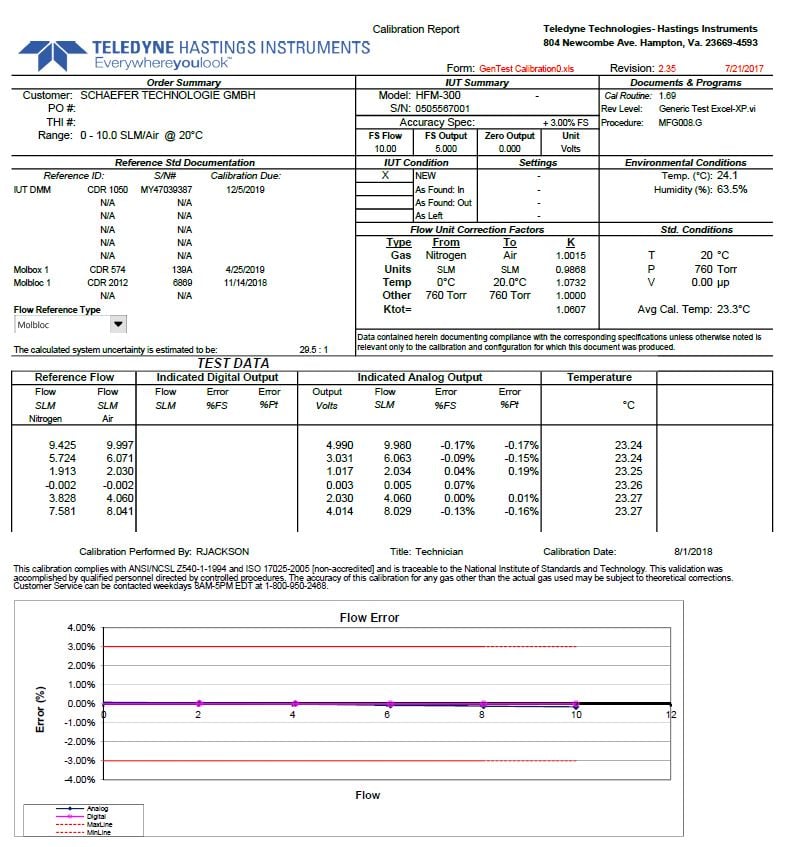

In this short blog, we are going to look at one of our mass flow controller calibration reports and discuss some of the terms that you will see. There is good information at the bottom of these reports, so let’s jump in and take a closer look…

At the bottom of every one of our calibration data sheets, you will see the following statement:

This calibration complies with ANSI/NCSL Z540-1-1994 and ISO 17025-2005 [non-accredited] and is traceable to the National Institute of Standards and Technology. This validation was accomplished by qualified personnel directed by controlled procedures. The accuracy of this calibration for any gas other than the actual gas used may be subject to theoretical corrections. Customer Service can be contacted weekdays 8AM-5PM EDT at 1-800-950-2468.

Let’s start with part of the first sentence, “This calibration complies with ANSI/NCSL Z540-1-1994 and ISO 17025-2005 [non-accredited]…” According to the NCSLI webpage , there are two national standards for calibration laboratories. These are Z540-1 and ISO 17025. There are some differences between the two standards. And the aforementioned NCSLI gives a detailed description of both. In short, 17025 is appropriate for both calibration and testing labs whereas Z540-1 addresses calibration labs only. 17025 requires that the laboratory be a legal entity that can demonstrate competency, which includes thorough analysis of the uncertainty associated with the calibration services. Another difference between the two standards is that 17025 places the responsibility of the calibration due date on the end-user. In other words, the calibration lab should not determine the customers calibration cycle. That is why you no longer see calibration due dates on Teledyne Hastings’ labeling.

OK…. if 17025 is the latest, greatest, and accepted around the world, why do we still even list Z540-1 on our calibration reports? Because, we still have customers who adhere to Z540-1 and need the statement on their paperwork.

What about the word “non-accredited” that appears in parentheses? While we strive to conform to ISO 17025, which includes rigorous internal audit review, it has been our position that as a manufacturer, it is not necessary / appropriate for us to invest in the accreditation activities and third party audits. However, we do recognize the depth and critical nature of the standard. Because of those criteria, we have chosen to compose our procedures and train our personnel to be in compliance with the standard. So to be clear, Teledyne Hastings is not accredited to ISO 17025.

Let’s move on… what do we mean by, “…traceable to the National Institute of Standards and Technology”? Simply this, we can provide an unbroken chain of calibration documents that connect your calibration back to NIST, the National Institute of Standards and Technology.

Now here is a trick question… does a NIST traceable calibration tell us anything about the uncertainty of the calibration? The answer is, “no”. For example, we could calibrate one of our most advanced mass flow controllers, the HFC-D-302B 300 Vue which has a stated uncertainty of ± (0.5% of Reading + 0.2% of Full Scale).

– or we could calibrate our HFC-202 flow controller (±1% of full scale using the same metrology and the stated uncertainty for each instrument would be the same as before. In other words, the performance of these instruments does not improve just because a NIST traceable standard was used.

One more note, some customers request “Backup Documentation” to their calibration data reports. In other words, they want copies of the calibration reports of our metrology that form the unbroken link from their calibration back to NIST. There is a nominal administrative fee to collect, scan, compile, and email these calibration reports for each individual piece of metrology that was used.

Does everybody need the Backup Documentation? Usually not, but enough customers request these so it is a service that we offer. Quite often the reason why our first tier customer will request the additional supporting calibration reports is because they are manufacturing complex assemblies that their higher tier customers are procuring with the aforementioned unbroken chain back to NIST as a purchase order flow down requirement.

Next, we have the sentence, “This validation was accomplished by qualified personnel directed by controlled procedures” This gives us an opportunity to tell a little about our ISO 9001:2015 Quality System. As a key part of our system, all assembly and calibration personnel must complete rigorous training and demonstrate proficiency before working on either the Flow Products or Vacuum Products Teams. Also, every product or subassembly acceptance test, that has a measurable output, is controlled by a top tier Quality System Procedure. The procedures, training program, in fact the entire Quality System is subject to routine internal audit program, third party surveillance audits, and third party ISO 9001:2015 certification audits.

Now what about the statement, “The accuracy of this calibration for any gas other than the actual gas used may be subject to theoretical corrections”? There are certain gases which are hazardous and/or corrosive. While our flow meters and controllers are quite suitable for use in many of these gases, there are several of the gases that we have never (and will never) allow into our facility. So, we use theoretical corrections to map the output of our flow products using the calibration gas to the output for the user’s gas.

We are very proud of our metrology and quality programs. And we welcome your questions. If you have a question about mass flow controllers, vacuum gauges, or just want more information about a Calibration Report, we are here to help. You can contact us at hastings_instruments@teledyne.com or call 757-723-6531 (800-950-2468).

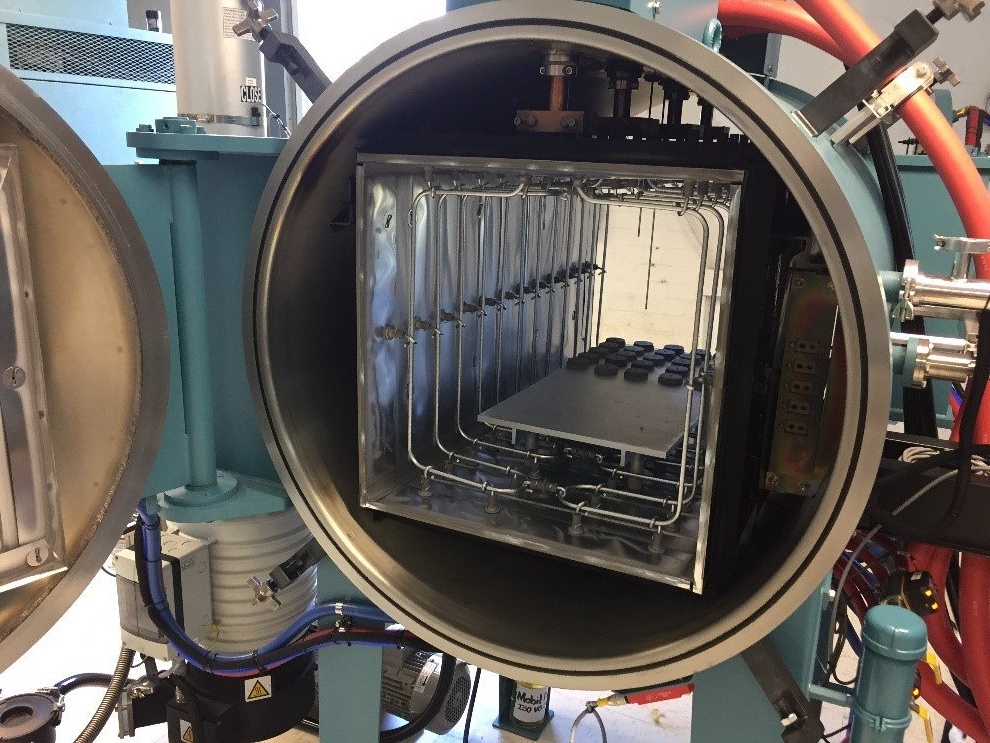

Inside the hot zone. Note the series of Molybdenum rod elements.

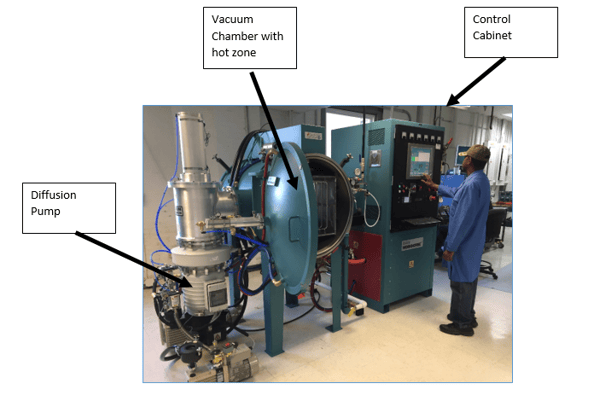

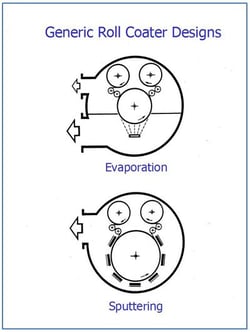

Inside the hot zone. Note the series of Molybdenum rod elements. Teledyne Hastings designs and build mass flow controllers for a broad array of markets from clean laboratory environments to heavy industrial installations. Recently, we have been asked to provide our newest line of Digital 300 Flow Meters and Controllers into more demanding environments. And, we are proud to offer an optional IP-67 enclosure, which provides protection against dust and water. More on our product later in the blog.

Teledyne Hastings designs and build mass flow controllers for a broad array of markets from clean laboratory environments to heavy industrial installations. Recently, we have been asked to provide our newest line of Digital 300 Flow Meters and Controllers into more demanding environments. And, we are proud to offer an optional IP-67 enclosure, which provides protection against dust and water. More on our product later in the blog. Which now brings us back to the

Which now brings us back to the

February is the month when citizens in the United States celebrate the history and culture of African-Americans. In early Feburary, scientists from the Pressure & Vacuum Group at NIST (National Institute of Standards & Technology) installed a special case designed to hold President Abraham Lincoln’s first handwritten draft of the Emancipation Proclamation and 13th Amendment in the Smithsonian’s National Museum of African American History & Culture. You can watch a video of the installation here:

February is the month when citizens in the United States celebrate the history and culture of African-Americans. In early Feburary, scientists from the Pressure & Vacuum Group at NIST (National Institute of Standards & Technology) installed a special case designed to hold President Abraham Lincoln’s first handwritten draft of the Emancipation Proclamation and 13th Amendment in the Smithsonian’s National Museum of African American History & Culture. You can watch a video of the installation here: Now, another interesting thing we can celebrate about the Emancipation Proclamation is the famous Emancipation Oak. Located on the campus of Hampton University, in Hampton Virginia. Note that Hampton is also the home of Teledyne Hastings. The Emancipation Oak was the site of the first reading of the Proclamation in the South according to the Hampton University Website (

Now, another interesting thing we can celebrate about the Emancipation Proclamation is the famous Emancipation Oak. Located on the campus of Hampton University, in Hampton Virginia. Note that Hampton is also the home of Teledyne Hastings. The Emancipation Oak was the site of the first reading of the Proclamation in the South according to the Hampton University Website ( We held a webinar on thermal mass flow meter / controller calibration best practices. Topics included:

We held a webinar on thermal mass flow meter / controller calibration best practices. Topics included:

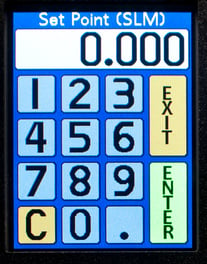

Teledyne Hastings is proud to release our newest, most advanced, line of digital flow meters and flow controllers - the 300 Vue. In this blog, we will discuss the three types of Input/Output (I/O) that can be used with the 300 Vue. These are: Analog, Digital, and Touchscreen Display.

Teledyne Hastings is proud to release our newest, most advanced, line of digital flow meters and flow controllers - the 300 Vue. In this blog, we will discuss the three types of Input/Output (I/O) that can be used with the 300 Vue. These are: Analog, Digital, and Touchscreen Display.

There are many benefits for having a Flow Service Plan for your Mass Flow Meters/Controllers. This blog touches on just a few of them.

There are many benefits for having a Flow Service Plan for your Mass Flow Meters/Controllers. This blog touches on just a few of them. Each instrument under the plan is eligible for three calibrations anytime within a 36-month period. Under the discount Flow Service Plan, the user purchases two calibrations and receives a third at no cost. At the time of purchase, the user may specify a calibration interval; Hastings Service will track the unit’s history and provide advance notice (four weeks) of the next scheduled calibration.

Each instrument under the plan is eligible for three calibrations anytime within a 36-month period. Under the discount Flow Service Plan, the user purchases two calibrations and receives a third at no cost. At the time of purchase, the user may specify a calibration interval; Hastings Service will track the unit’s history and provide advance notice (four weeks) of the next scheduled calibration. The calibration and service department will clean, recalibrate, and ship the instrument back to the user within 5 working days or less per instrument. The Flow Service Plan will improve up-time at the user’s facility while ensuring compliance to metrology requirements. All calibration performed at Teledyne Hastings is traceable to the National Institute of Standards and Technology (NIST). In addition to this, calibrations are compliant to ISO 17025 requirements.

The calibration and service department will clean, recalibrate, and ship the instrument back to the user within 5 working days or less per instrument. The Flow Service Plan will improve up-time at the user’s facility while ensuring compliance to metrology requirements. All calibration performed at Teledyne Hastings is traceable to the National Institute of Standards and Technology (NIST). In addition to this, calibrations are compliant to ISO 17025 requirements.

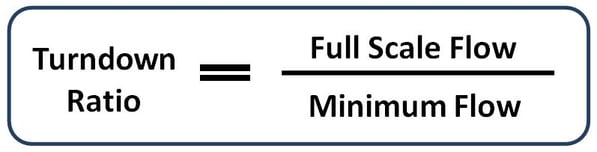

A flow meter with a large turndown ratio will have a large operating range. This can also be indicative of the flow meter’s cost. For example, variable area flow meters (rotameters) typically have lower turndown ratios compared to thermal mass flow meters.

A flow meter with a large turndown ratio will have a large operating range. This can also be indicative of the flow meter’s cost. For example, variable area flow meters (rotameters) typically have lower turndown ratios compared to thermal mass flow meters. Most analog mass flow controllers also have an accuracy of ± 1% FS. However, they typically have an automatic valve shut circuit that closes the valve at flow rates below 2% of FS. This is to ensure full valve closure in the event of a small zero offset. The usable range is from 2% to 100%. Since measurement is not possible below 2%, these will have a turndown ratio of 100/2 = 50/1 or 50:1.

Most analog mass flow controllers also have an accuracy of ± 1% FS. However, they typically have an automatic valve shut circuit that closes the valve at flow rates below 2% of FS. This is to ensure full valve closure in the event of a small zero offset. The usable range is from 2% to 100%. Since measurement is not possible below 2%, these will have a turndown ratio of 100/2 = 50/1 or 50:1.