A Pirani vacuum gauge is a type of thermal conductivity gauge that is also often referred to as a “thermal heat transfer gauge”. In a Pirani gauge, the rate of heat transfer is a function of the number of gas molecules present in the vacuum system. Pirani gauges are capable of providing reliable pressure measurement in a wide variety of vacuum technology applications.

What is the working principle of the Pirani Vacuum Gauge?

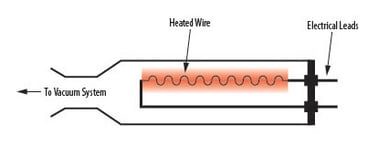

A Pirani vacuum gauge contains a heated component, such as a wire or thin-film membrane (see figure on right), which is brought to an elevated temperature, typically through the use of a bridge circuit. As changes in gas molecular density occur, the transfer of heat from the wire to the gas is affected. This heat loss is dependent on gas type and pressure, and the amount of energy required to keep the wire at temperature varies accordingly. Consequently, the amount of energy is dependent on vacuum pressure and can be converted to a pressure value.

A Pirani vacuum gauge contains a heated component, such as a wire or thin-film membrane (see figure on right), which is brought to an elevated temperature, typically through the use of a bridge circuit. As changes in gas molecular density occur, the transfer of heat from the wire to the gas is affected. This heat loss is dependent on gas type and pressure, and the amount of energy required to keep the wire at temperature varies accordingly. Consequently, the amount of energy is dependent on vacuum pressure and can be converted to a pressure value.

Accurate pressure measurement depends on the ability of the bridge circuit to maintain very precise control of the sensor’s temperature. The most common technique is to use a Wheatstone bridge circuit. In one design of a Pirani bridge circuit, two legs of the bridge are controlled at the same voltage via an electronic feedback loop. The measurement technique then is to quantitate the power required to maintain the heated sensor at a given temperature above ambient. (See J. Vac. Sci. Technol. A 13(6), Nov/Dec 1995)

In the case of a gauge that employs a heated sensor wire, there are three main heat loss routes: bulk thermal conduction via the wire and its supports, radiation losses, and thermal conduction losses through the gas. It follows that a well-designed Pirani vacuum gauge minimizes loss of signal due to radiation and bulk thermal conduction. Radiation losses are strongly (fourth power) dependent on the temperature of the heated sensor. Consequently, when operating a Pirani gauge, it is important to keep the sensor at a low enough temperature such that the radiation loss mechanism does not dominate the overall signal. Similarly, a well-designed Pirani gauge minimizes bulk thermal conductivity via the sensor element. For both radiation and bulk thermal conductivity losses, the loss factors are dependent on temperature.

What are the advantages of the Pirani Vacuum Gauge?

The Pirani vacuum gauge offers numerous advantages. Foremost, the gauges are typically very easy to use and can provide years of trouble-free, reliable pressure measurement, because they have no moving parts. Additionally, they are highly economical, costing far less than capacitance manometers. Flexibility in output monitoring includes local displays, analog output, and/or digital communication. Pirani vacuum gauges are relatively fast and are very responsive to changes in the vacuum system’s pressure. Gauges with very small internal dimensions can offer increased response speed. It should be noted that convection-enhanced Pirani vacuum gauges require larger volumes to support convection currents and may therefore have slower response, simply due to the larger volume that must be evacuated inside the tube. Convection-enhanced Pirani vacuum gauges measure pressure up to atmospheric pressure, however, their accuracy in gases other than air or nitrogen at elevated pressure, can be very poor.

Combination gauges, such as Teledyne Hastings’ HVG-2020B, combine a piezo-based sensor with a conventional, thermal-based Pirani sensor to provide accurate pressure measurement from 10-4 Torr (0.1 mTorr) to 10+3 Torr. Additionally, by combining the two technologies in one gauge, the errors associated with the gas composition specific Pirani sensor are eliminated at pressures above 10 Torr.

What are some of the applications for Pirani Vacuum Gauges?

Many Pirani vacuum gauges measure pressure from below 1 mTorr up to atmosphere and are a very good choice for a wide variety of applications:

- Pirani vacuum gauges are used to monitor the pump down from atmosphere to the start of the high vacuum region (where turbomolecular pumps or other high-vacuum pumps take over)

- In the vacuum metallurgy industry (high-purity alloys manufactured in a controlled environment) Pirani vacuum gauges ensure process consistency and optimization of different thin-film coating systems.

- Freeze dryers and vacuum dryers frequently operate in a vacuum region that is well-suited to Pirani vacuum gauges, as well as the manufacture and maintenance of cooling systems (air conditioning, ice machines, and refrigeration).

- Various analytical instrumentation requires vacuum levels in and below the mTorr region, and the Pirani gauge is often the most cost-effective instrument for these applications.

FAQs

What are some best practices for Pirani Vacuum Gauges?

Pirani gauges have no moving parts and generally do not require maintenance. It should be noted that this type of gauge is susceptible to contamination, especially in oil-based pumping systems. In systems with contamination, the gauge tube should be installed with the port facing downward to reduce oil accumulation inside the tube.

Convection-driven Pirani vacuum gauges should always be installed with the cylindrical axis parallel to the floor. Failure to install this type of gauge properly will lead to erroneous readings above the rough vacuum level.

If the vacuum system has excessive oil vapor or other contaminants, a molecular sieve filter can be used to extend the service life of the gauge.

For information on Teledyne Hastings Vacuum Gauges, visit https://www.teledyne-hi.com/products-services/vacuum-measurement-and-control or click the button below to contact us for more information.